SH Electronics Co. is one of the leading manufacturers of CNC Cutting Machines.

Being an ISO 9001:2015 company is engaged to providing best quality machines with reasonable prices.

SH Electronics Co. is a Pune based and professionally managed manufacturing organization with more than three decades in its field of new era in electronics. The Company is engaged in the field of power electronics, telecommunication & digital electronics. Company is in the field of Electrical Equipments like D'CONS (Since 1979) Servo Controlled Voltage Stabilizers, CVT's, Voltage Correctors, Transformers, SPM Control Panels, D-SCALL Computerized Controlled Water Conditioners, SMPS, DC-DC converters, Battery Chargers & Dischargers, Inverters & UPS. Well-Known "HOME PROTECTORS" ( high voltage preventors) for domestic & Industrial use. PMDC motor drives.

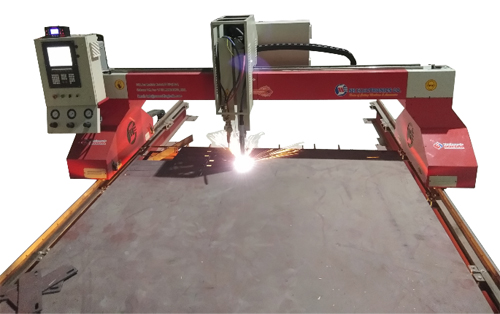

Since a decade Company is engaged in manufacturing high quality Equi-CUT, PRO-CUT, TABLE STYLE, MULTI TROCH Series CNC Oxy-fuel & Plasma cutting machines, CNC Profile cutting machines, Plasma Sources, Welding Machines and Automation Products.

The company is also engaged in providing CCD, DVR, Surveillance services to the corporate offices, banks, companies and institutions. The company is run by a highly qualified and experienced team is managed by its people, believes in delegation of authority and our corporate policy encompasses views and opinions of all personnel and above all, our customers. The Series machine from SH Electronics Co. has the perfect entry level as well as high end model for profile cutting, plasma cutting, cnc plasma cutting, cnc cutting machine, gas cutting machine, cnc profile cutting solution. Any complicated shape can cut by CNC cutting machine easily with less time. Job working units or manufacturer can easily use these machines comfortably. Each machine includes a CNC control, rail system, nesting software and high-speed motors & drivers, plasma cutting system can also integrate with machines as per requirement.

We Have Complete Solution in cnc cutting, the Series machine from SH Electronics Co. has the perfect entry level as well as high end model for profile cutting, plasma cutting, cnc plasma cutting, cnc cutting machine, gas cutting machine, cnc profile cutting solution. Any complicated shape can cut by CNC cutting machine easily with less time. Job working units or manufacturer can easily use these machines comfortably. Each machine includes a CNC control, rail system, nesting software and high-speed motors & drivers, plasma cutting system can also integrate with machines as per requirement.

The Series machine from Equipments India has the perfect entry level as well as high end model for profile cutting, plasma cutting, cnc plasma cutting, cnc cutting machine, gas cutting machine, cnc profile cutting solution. Any complicated shape can cut by CNC cutting machine easily with less time. Job working units or manufacturer can easily use these machines comfortably. Each machine includes a CNC control, rail system, nesting software and high speed motors & drivers, plasma cutting system can also integrate with machines as per requirement.

![]()

Series machine delivers productivity. ADTECH CNC, Hyper-therm control provides precision motion control for both high-speed plasma and Oxy-fuel cutting. Original Micro EDGE TM control system produced by Hypertherm, USA. Micro EDGE TM CNC system is the most advanced one developed by Hypertherm Corporation, USA on the basis of windows interface for plasma, flame, laser and high-pressure water cutter The interface design, cutting speed and motion control of this system adopt the newest technology. It features powerful function and convenient operation. It is the most intellectualized system in cutting process. Arc-off time between parts is extremely short with a rapid traverse speed. Torch height control rapidly sets pierce height and maintains precise torch to plate distance while cutting-no matter what the travel speed.

• Consumable life improvement

• Improved cut quality

• Reduced operator intervention. For better consumable life.

• Spatter during piercing presents a threat to the nozzle and shield.

• Setting the height of the torch higher during piercing protects the consumables by moving them away from the spatter.

![]()

Heavy duty – high performance Oxy-fuel components are your guarantee of superior productivity. The optional gas system includes twin sets of high and low pre-heat regulators to produce fast pierce rates and balanced torch flames, even with multiple torches. A domed high-flow oxygen regulator ensures uniform pierce rate control and outstanding flow capacity. The standard torches are designed for cutting plate up to 200/ 300mm thick.

![]()

Equipments India can provide you complete training with a variety of professional MTC, Sigma nest or Radan make nesting software packages. Nesting software, for conventional plasma and oxy fuel applications, delivers best-in-class performance and reliability yet is also incredibly easy to learn and use. With Turbo Nest you will experience flexible import of your 2D CAD files, material cost savings from efficient nesting, and repeatable results from parameter-based setups that provide consistent cut quality and productivity, along with reduced operating costs. Turbo Nest offers the solutions you need to process your jobs quickly, easily, and profitably.